createSolid-Verify

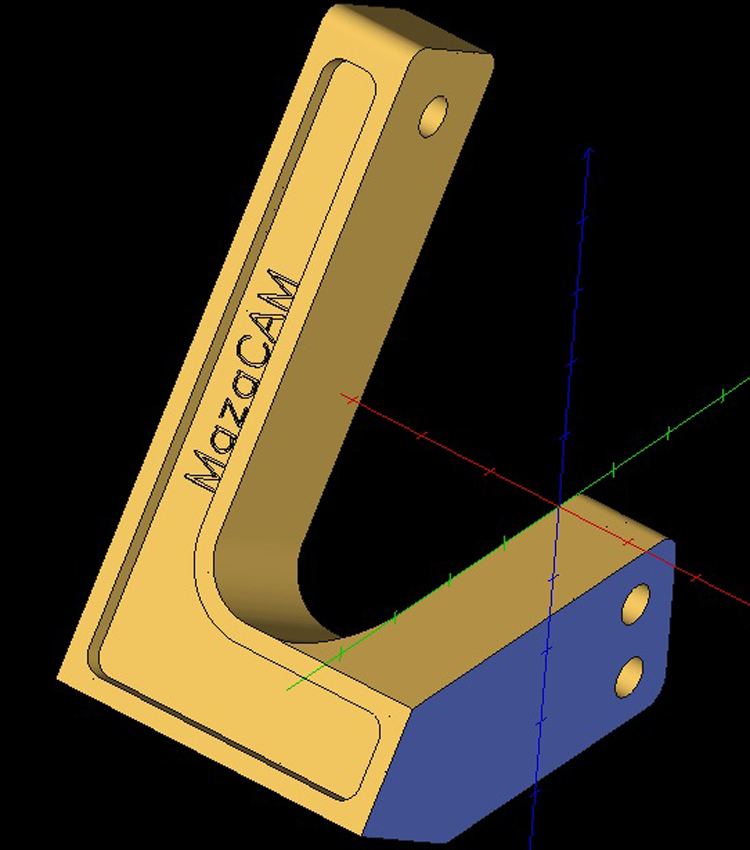

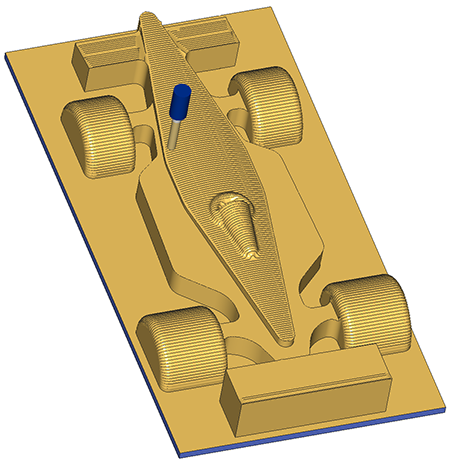

The Solid-Verify module helps shops save time by verifying CNC programs on computer before putting them on machine. Shows cuts, rapid crashes, tools and holders, form tools, and user-defined tools on computer before going to CNC. Undesirable rapid moves through the part are identified on the computer screen.

Features

- Perform solid verification for 3D mill, 2-axis lathe, and live C/Y-axis applications, including Integrex, etc.

- Fixtures, vices, and chucks (including lathe main and sub-spindle) can be included in the model if desired for even more verification of the set-up and machining.

- Ability to see inside the part to check what is happening.

- Show only the tool for easier definition, or tool plus holder for more complete verification.

- Optional different cut-surface color per tool to make it obvious what was cut with what tool.

- With MazaCAM, Solid-Verify makes it possible for users of all generations of Mazatrol controls - from legacy to the very latest (except T4).

- Solid-Verify makes it possible for users of any standard G-code machine to do solid verification for 3D mill, 2-axis lathe, and live C/Y-axis applications.

Would any of these benefit your shop?

- See a rendition of the finished part to make sure it is what you have in mind generally, and also zoom in to see things at a detail level

- Helps to catch crashes on the computer before they go to the CNC

- Visually see how one cutting strategy might work out compared to another strategy, you can do this quickly on the computer before spending a lot of time trying it on the CNC machine

- Output an STL file of the result, that can be used as the starting material for next processes, or in other systems to make sure parts fit with other pieces of the assembly, etc.

Note: It is impossible to catch every possible issue in a computer simulation.

Safe operation of the equipment and accuracy of the parts made are the responsibility of the user.

Contact us to get a demonstration on how MazaCAM can help you increase productivity in your shop today

Contact Us